Blog Details

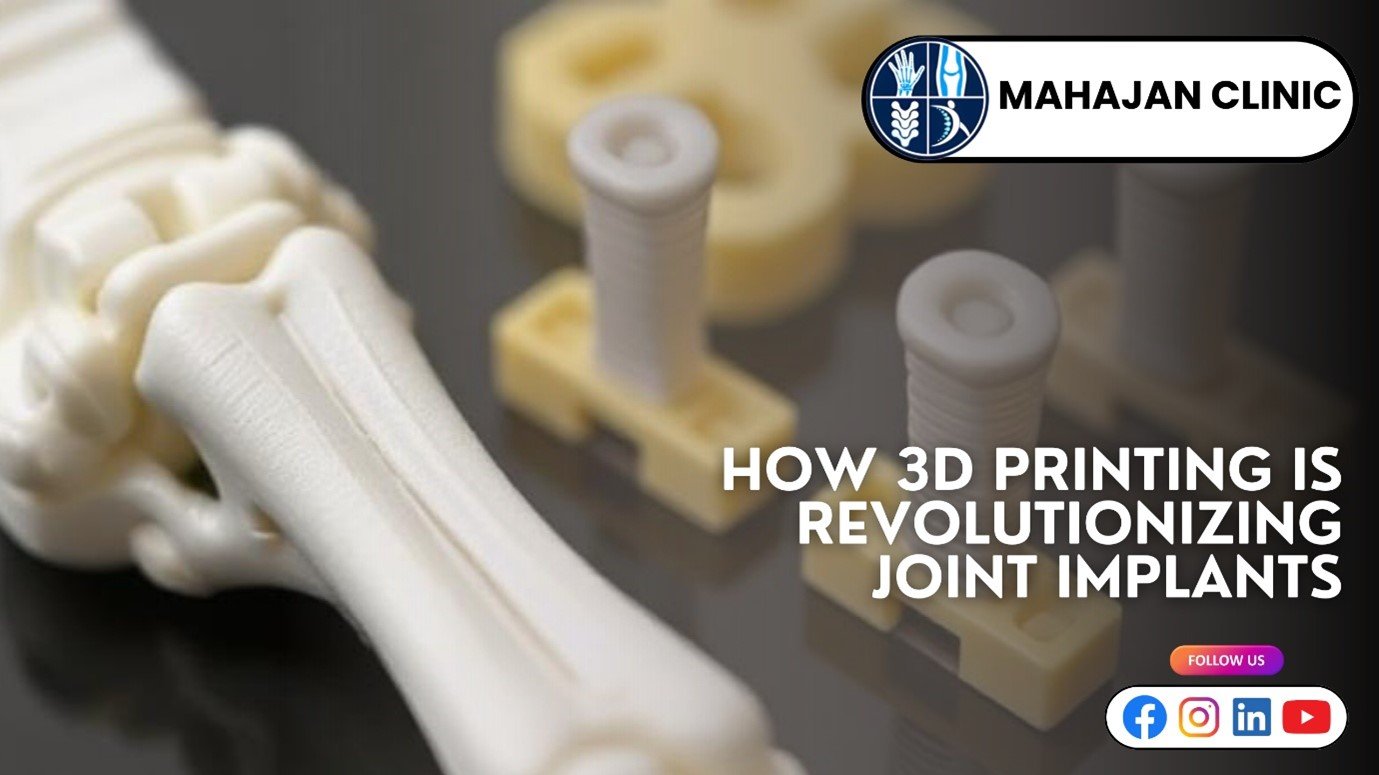

How 3D Printing Is Revolutionizing Joint Implants

Orthopaedic surgery has entered a new era with the emergence of 3d printing for joint implants. With solutions that are more accurate, individualized, and effective than ever before, this state-of-the-art technology is completely changing the way surgeons perform joint replacement surgeries. Leading the way in the use of cutting-edge medical technology, Dr. Rakesh Mahajan at Mahajan Clinic has been heavily indulged in the concept of 3D printing to give patients better results and quicker recuperation times.

Limitations of Traditional Joint Implants

Standardized implants were used for decades in joint replacement procedures, including hip, knee, shoulder, and ankle replacements. These implants are designed to fit a wide variety of patients and are available in preset sizes and shapes. They have limitations even though they have been successful in giving millions of people their mobility back. An individual's anatomy may not be precisely matched by generic implants, which can cause discomfort, unequal load distribution, and in certain situations, the need for revision surgery.

Conventional implants also require a long production process. Sometimes taking weeks or months, it entails casting, moulding, machining, and sterilization. This inflexibility can hinder the ability to handle particular anatomical challenges and postpone necessary procedures.

How 3D Printing Is Changing the Game

3d printing for joint implants offers a transformative alternative. Implants can now be made layer by layer using additive manufacturing in accordance with an exact digital model obtained from the patient's joint's CT or MRI scans. This guarantees a personalized fit that precisely matches the patient's distinct bone structure.

There are important ramifications: Implants that fit better increase mobility, lower the chance of problems, and last longer. Compared to patients receiving standard implants, patients frequently need less time for rehabilitation and have fewer post-operative problems.

Personalized Implants for Diverse Needs

One of the standout advantages of 3d printing for joint implants is its capacity to develop genuinely patient-specific solutions. For people with severe joint degeneration, deformities, or complex bone structures, this is especially crucial. For instance:

- A perfectly contoured hip implant that naturally aligns with the pelvis can be given to a patient who has a congenital hip deformity.

- Knee implants that mimic the biomechanics of the original joint can help athletes recuperating from severe knee injuries resume their activities more quickly.

- Implants with a porous structure can be given to elderly patients who have osteoporosis-related bone loss in order to promote bone stability and integration.

Longevity and functional results may be enhanced by custom implants that maximize load distribution and lessen stress on the surrounding bone.

Faster Production and Cost-Effectiveness

Conventional implants must go through several manufacturing steps, which can take several weeks. In contrast, 3d printing for joint implants drastically cuts down on production schedules. Depending on its complexity, printing a digital model can take hours or even days after it is ready. This quick procedure is particularly helpful for patients who require revision surgery or for urgent cases.

Additionally, there is very little material waste produced by additive manufacturing. While 3D printing uses only the material required to construct the implant, traditional machining removes excess metal from blocks, producing scrap. This effectiveness eventually results in financial savings for patients as well as hospitals.

Advanced Materials and Biocompatibility

Biocompatible materials like titanium alloys and medical-grade polymers can be used with modern 3D printing. Because of its strength, resistance to corrosion, and compatibility with the human body, titanium is especially preferred. 3D printing can be used to create implants with porous surfaces that promote osseointegration, or the integration and growth of bone.

Additionally, bioactive and composite materials that promote healing and lower the risk of infection are being tested by researchers. With 3d printing for joint implants, it is possible to create intricate geometries like lattice structures, which enhance patient outcomes and mechanical performance.

Surgical Planning and Simulation

The use of 3D printing in pre-operative planning is another important advantage. Before going into the operating room, surgeons can visualize and simulate the procedure by building patient-specific models of the joint. These models aid in identifying possible issues, figuring out the ideal implant size, and honing the surgical technique.

This planning improves surgical precision, decreases errors, and shortens the operating time. Patients gain from quicker recovery times, fewer complications, and more predictable results.

Environmental Benefits

Additionally, 3D printing has environmental benefits. Compared to conventional implant production, additive manufacturing uses less energy and produces fewer waste products. Hospitals can lessen the carbon footprint related to manufacturing and transportation by using only the necessary materials and possibly producing implants locally or on-site.

The importance of sustainability in healthcare is growing, and 3D printing fits in well with these objectives while offering patients real advantages.

Challenges and Considerations

There are difficulties with 3D printing joint implants, despite its potential. For patient-specific implants, regulatory approval procedures are strict and necessitate extensive testing to guarantee efficacy and safety. Although costs are gradually falling as the technology advances, high-quality biocompatible materials and 3D printers can still be quite expensive.

Not every patient needs customized implants, which is another crucial point to remember. For many people, standard implants are still very effective, especially those with normal joint anatomy and minimal surgical complexity. To decide when a 3D printed implant is the best option, clinical judgment is essential.

The Future of 3D Printed Joint Implants

3D printing holds great promise for joint implants in the future. Revision surgeries may become less necessary as a result of advancements in bioresorbable materials, which progressively fuse with natural bone. Furthermore, real-time temperature, load, and stress monitoring could be possible with smart implants that have sensors built in, giving surgeons and patients useful information.

3D printing is a key component of the shift toward personalized medicine. Patients can anticipate joint implants that are not only functional but also tailored to their particular anatomy, way of life, and long-term health as technology develops.

Final Summary

Custom, accurate, and effective joint replacements are made possible by 3D printing for joint implants, which is completely changing orthopaedic surgery. Improved functional outcomes, quicker production times, more sustainable medical solutions, and better-fitting implants all benefit patients. By using this technology, Dr. Rakesh Mahajan of Mahajan Clinic aims to set the standard for individualized orthopaedic care, assisting patients in regaining their mobility, minimizing discomfort, and enhancing their quality of life. Personalized, accurate, and patient-centred joint implants are the way of the future.